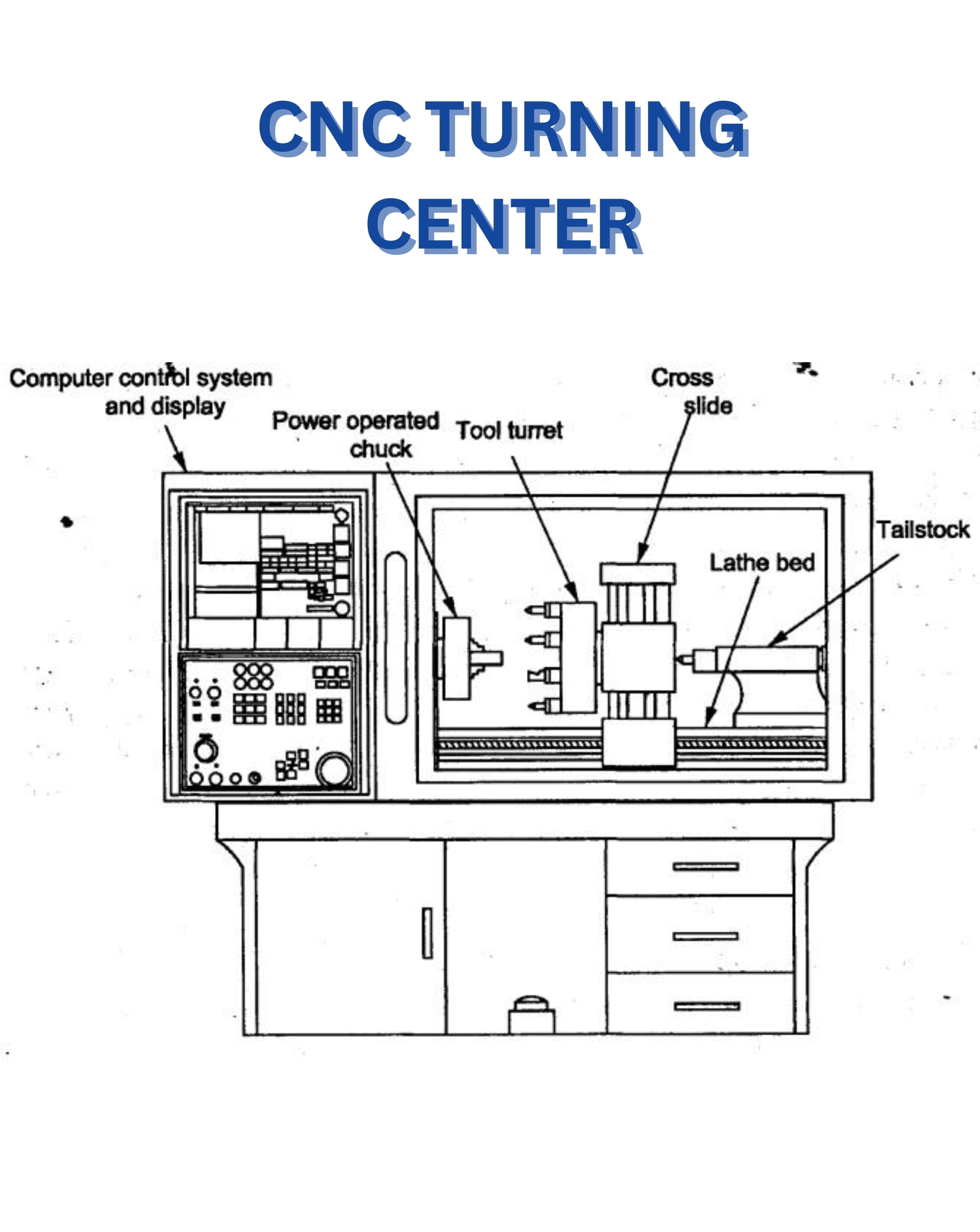

TURNING CENTER PROGRAM

Other Chapters

INTRODUCTION TO NUMERICAL CONTROLNC MACHINE TOOL CHARACTERISTICSTYPES OF MACHINE TOOLSCONFIGURATION AND CONTROL METHOD OF NC MACHINE TOOLSACCESSORIES TOOLS AND CUTTING FLUIDTURNING CENTER PROGRAMMACHINING CENTER PROGRAMAUTOMATED MANUFACTURING SYSTEMCONDITION FOR CUTTINGCUTTING TOOLS AND CHIPSSELECTING A TYPE OF TOOL MATERIAL

- Q1: What is the Machining Process of Turning Center?Ans: The machining process of a turning center involves rotating the workpiece while the cutting tool removes material to obtain the desired shape.

- Q2: Define Rough Boring.Ans: Rough boring is a machining operation used to enlarge a hole by removing a large amount of material.

- Q3: Define Finish Boring.Ans: Finish boring is a machining operation used to improve the accuracy and surface finish of an existing hole.

- Q4: Define Grooving.Ans: Grooving is a machining process used to cut narrow channels or grooves on a workpiece.

- Q5: Define Contour Turning.Ans: Contour turning is a turning operation used to produce complex curved profiles on a workpiece.

- Q6: What is the Tooling for Turning Center?Ans: The tooling is as under:

- ➔ Turning tools

- ➔ Boring tools

- ➔ Grooving tools

- ➔ Parting tools

- ➔ Drilling tools

- Q7: Define Tool Fixing.Ans: Tool fixing is the method of securely mounting cutting tools on the turret or tool holder.

- Q8: What are the co-ordinate systems of the Turning Center?Ans: Following are the co-ordinate systems of the Turning Center:

- ➔ Rectangular coordinate system

- ➔ Polar coordinate system

- Q9: What is the Rectangular Co-ordinate System?Ans: The rectangular coordinate system defines positions using X and Z axes.

- Q10: What is the Polar Co-ordinate System?Ans: The polar coordinate system defines positions using distance and angle.

- Q11: What is the difference between Zero Point and Reference Point?Ans: Zero point is the programmed origin for machining, while reference point is a fixed machine home position.

- Q12: Define CNC Program.Ans: A CNC program is a set of instructions that controls the movement and operation of a CNC machine.

- Q13: Define Part Program.Ans: A part program is a CNC program specifically written to machine a particular component.

- Q14: Define Sub Program.Ans: A sub program is a smaller program used repeatedly within a main CNC program.

- Q15: Define G-code.Ans: G-code is a programming code used to control machine movements and machining functions.

- Q16: Define M-code.Ans: M-code is a programming code used to control auxiliary machine functions.

- Q17: Name the types of G-code.Ans: Following are the types of G-code:

- ➔ One-shot G-code

- ➔ Modal G-code

- Q18: Define One-shot G-code.Ans: One-shot G-code is effective only for a single block of the program.

- Q19: Define Modal G-code.Ans: Modal G-code remains active until it is cancelled or replaced by another code.

- Q20: Write some G-codes for turning center.Ans: Some of the G-codes for turning center are as follows:

- ➔ G00 — Positioning Rapidly

- ➔ G01 — Linear interpolation

- ➔ G02 — Circular interpolation (CW)

- ➔ G03 — Circular interpolation (CCW)

- ➔ G31 — Skip function

- Q21: Write some M-codes for turning center.Ans: Some of the M-codes for turning center are as follows:

- ➔ M02 — End of Program

- ➔ M03 — Rotation of Spindle ON (CW)

- ➔ M05 — Spindle stop

- ➔ M06 — Tool change

- ➔ M09 — Coolant OFF

- Q22: Define turning center program.Ans: A turning center program is a CNC program used to perform turning operations on a turning center.

- Q23: Define Reference Point Setting.Ans: Reference point setting is the process of moving the machine to its fixed home position.

- Q24: When M39 code is used?Ans: M39 code is used to open or release the chuck in a turning center.

- Q25: When will the G04 code be used?Ans: G04 code is used to provide a dwell or pause for a specified time.

- Q26: When will the G71 code be used?Ans: G71 code is used for rough turning operations.

- Q27: What is Program Zero?Ans: Program zero is the origin point from which all machining dimensions are measured.

- Q28: When will the M02 code be used?Ans: M02 code is used to end the CNC program.

- Q29: When will the M03 code be used?Ans: M03 code is used to start the spindle in clockwise direction.

- Q30: When will the M06 code be used?Ans: M06 code is used to change the tool automatically.

- Q31: When will the M09 code be used?Ans: M09 code is used to turn OFF the coolant.

- Q32: Define Circular Interpolation.Ans: Circular interpolation is a machining process in which the tool moves along a circular path using G02 or G03 codes.