CUTTING TOOLS AND CHIPS

Other Chapters

INTRODUCTION TO NUMERICAL CONTROLNC MACHINE TOOL CHARACTERISTICSTYPES OF MACHINE TOOLSCONFIGURATION AND CONTROL METHOD OF NC MACHINE TOOLSACCESSORIES TOOLS AND CUTTING FLUIDTURNING CENTER PROGRAMMACHINING CENTER PROGRAMAUTOMATED MANUFACTURING SYSTEMCONDITION FOR CUTTINGCUTTING TOOLS AND CHIPSSELECTING A TYPE OF TOOL MATERIAL

- Q1: Define Cutting Tools.Ans: Cutting tools are devices used to remove material from a workpiece to give it the desired shape and size.

- Q2: Name the parts of Cutting Tools.Ans: The parts of Cutting Tools are as follows:

- ➔ Shank

- ➔ Flank

- ➔ Nose

- ➔ Cutting edge

- Q3: Define Shank.Ans: Shank is the portion of the cutting tool held in the tool holder or machine.

- Q4: Define Flank.Ans: Flank is the surface of the tool that faces the finished surface of the workpiece.

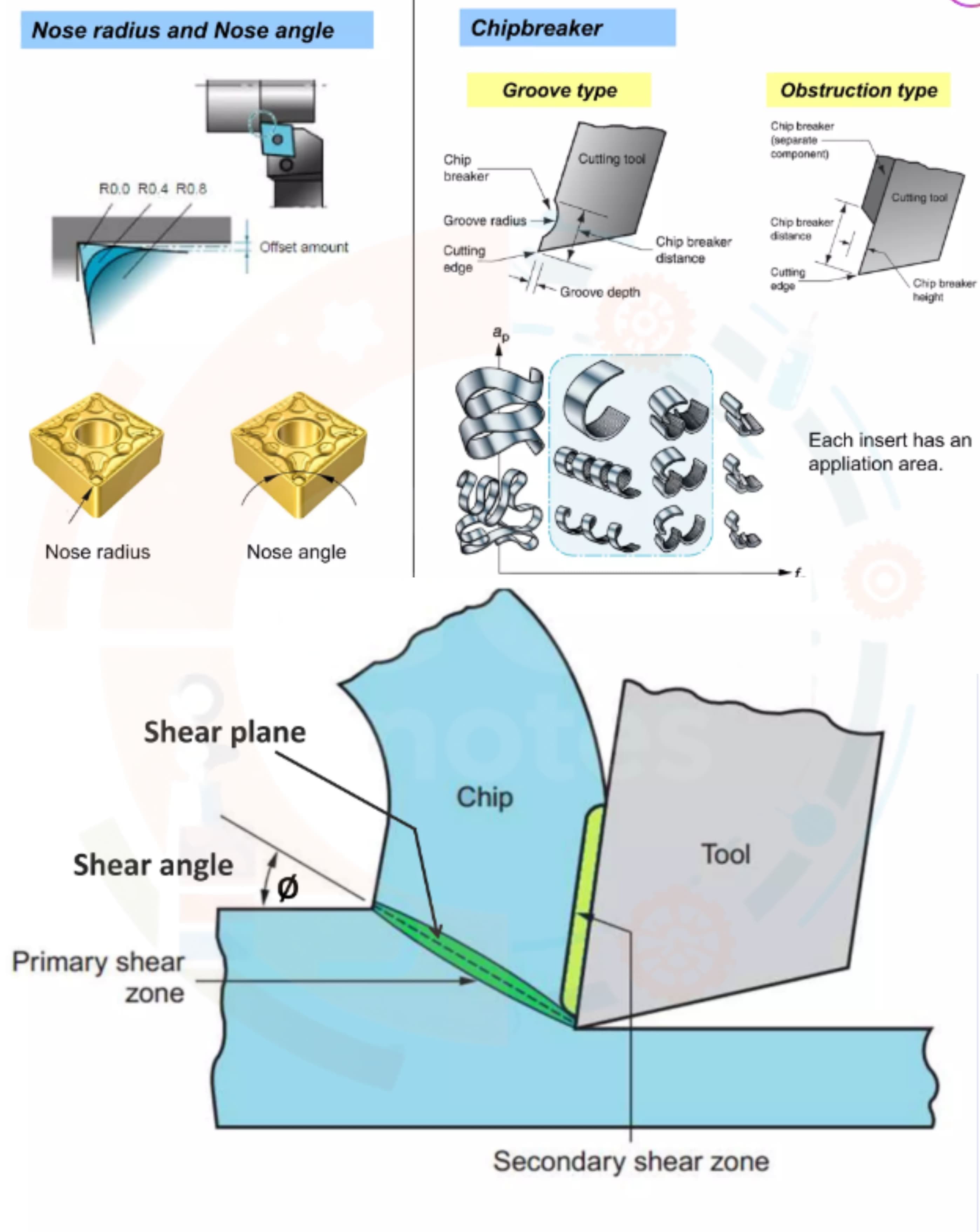

- Q5: Define Nose Radius.Ans: Nose radius is the rounded tip of the cutting tool where the cutting edges meet.

- Q6: Write the effects of Nose Radius.Ans: The effects of Nose Radius are as follows:

- ➔ Improves surface finish

- ➔ Increases tool strength

- ➔ Reduces cutting tool vibration

- Q7: Define Rack Angle.Ans: Rack angle is the angle formed between the cutting edge of a tool and the surface being machined.

- Q8: Write the types of Rack Angle.Ans: The types of Rack Angle are as follows:

- ➔ Positive Rack Angle

- ➔ Negative Rack Angle

- Q9: Define Positive Rack Angle.Ans: Positive rack angle means the cutting edge is inclined forward, reducing cutting forces.

- Q10: Write the effects of Positive Rack Angle.Ans: The effects of Positive Rack Angle are as follows:

- ➔ Reduces cutting force

- ➔ Produces smoother finish

- ➔ Increases tool life for softer materials

- Q11: Define Negative Rack Angle.Ans: Negative rack angle means the cutting edge is inclined backward, increasing tool strength for hard materials.

- Q12: Write the Negative of Positive Rack Angle.Ans: The negative rack angle is used for machining hard materials to prevent tool breakage, though it increases cutting force.

- Q13: Define Cutting Edge Angle.Ans: Cutting edge angle is the angle formed between the cutting edge of the tool and the direction of feed.

- Q14: Define Relief and Clearance Angle.Ans: Relief or clearance angle is the angle between the tool flank and the workpiece surface to prevent rubbing.

- Q15: Name the types of Cutting Tools.Ans: The types of Cutting Tools are as follows:

- ➔ Single-point cutting tool

- ➔ Multi-point cutting tool

- ➔ Diamond tool

- Q16: Define Chip.Ans: Chip is the material removed from a workpiece during the cutting process.

- Q17: Name the types of Chips.Ans: The types of Chips are as follows:

- ➔ Continuous Chip

- ➔ Discontinuous Chip

- ➔ Continuous Chip with Built-up Edge

- Q18: Define Continuous Chip.Ans: Continuous chip is a long, unbroken chip produced when cutting ductile materials with sharp tools.

- Q19: Define Dis-continuous Chip.Ans: Discontinuous chip is a short, broken chip produced when cutting brittle materials or using interrupted cuts.

- Q20: Define Continuous Chip with Built-up Edge.Ans: Continuous chip with built-up edge occurs when material sticks to the cutting edge, forming small lumps, often with ductile metals.

- Q21: Define Chip Conveyor.Ans: A chip conveyor is a device used to remove chips from the machining area to keep it clean and prevent damage.

- Q22: Define Airgun.Ans: An airgun is a tool used to blow away chips and dust from the workpiece and machine during or after machining.