SELECTING A TYPE OF TOOL MATERIAL

Other Chapters

INTRODUCTION TO NUMERICAL CONTROLNC MACHINE TOOL CHARACTERISTICSTYPES OF MACHINE TOOLSCONFIGURATION AND CONTROL METHOD OF NC MACHINE TOOLSACCESSORIES TOOLS AND CUTTING FLUIDTURNING CENTER PROGRAMMACHINING CENTER PROGRAMAUTOMATED MANUFACTURING SYSTEMCONDITION FOR CUTTINGCUTTING TOOLS AND CHIPSSELECTING A TYPE OF TOOL MATERIAL

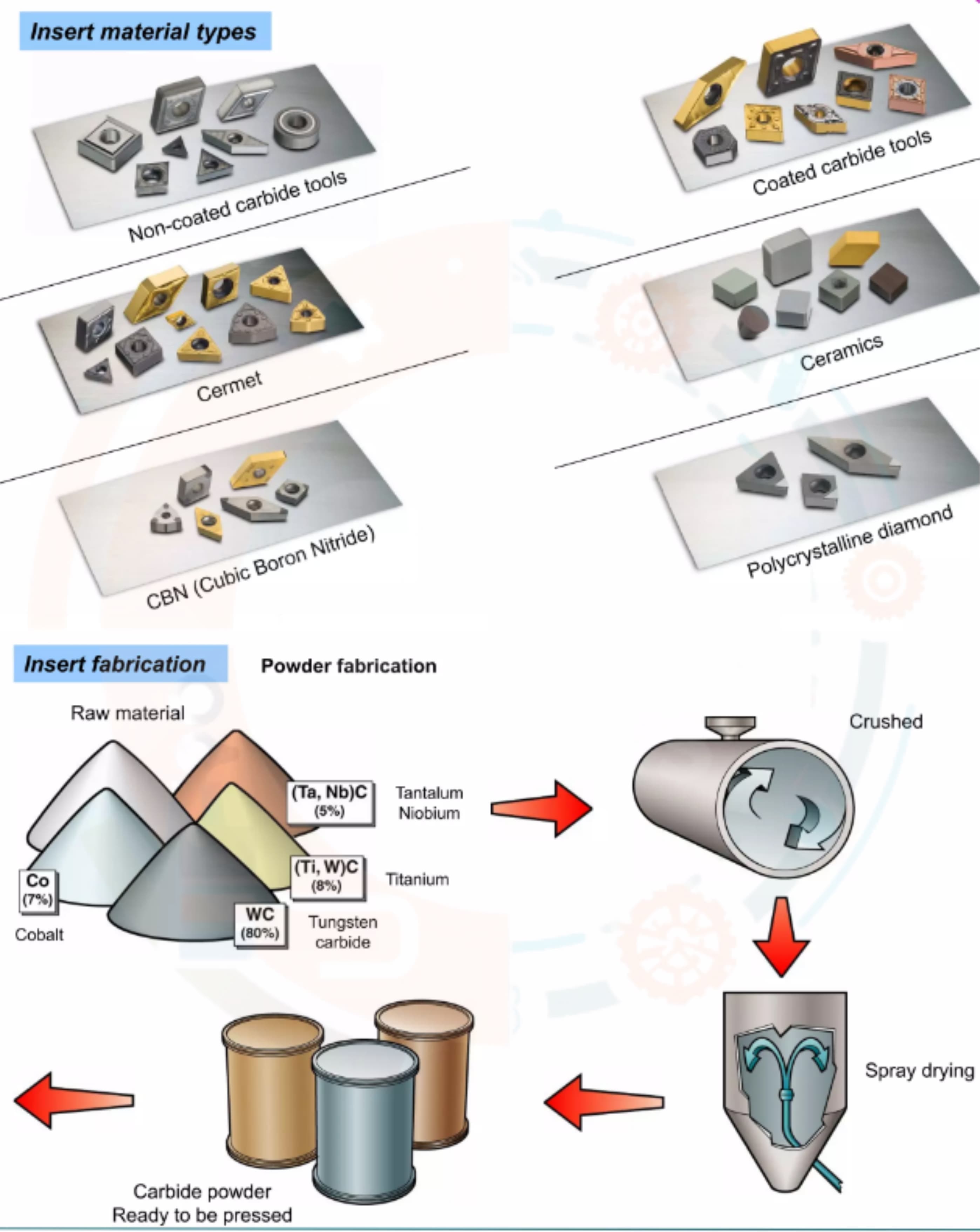

- Q1: Write the classification of Cutting Tool Material.Ans: Cutting Tool Materials are classified as follows:

- ➔ High-Speed Steel (HSS)

- ➔ Cemented Carbides

- ➔ Ceramics

- ➔ Cermets

- ➔ Cubic Boron Nitride (CBN)

- ➔ Diamond

- Q2: Write the properties of Cutting Tool Material.Ans: The properties of Cutting Tool Materials are as follows:

- ➔ High hardness

- ➔ Wear resistance

- ➔ Toughness

- ➔ Heat resistance

- ➔ Chemical stability

- Q3: Define HSS.Ans: HSS (High-Speed Steel) is a type of steel that can withstand high cutting temperatures without losing hardness.

- Q4: Define M-group.Ans: M-group refers to HSS steels alloyed with molybdenum for improved wear resistance and toughness.

- Q5: Define Cemented Carbide Tools.Ans: Cemented carbide tools are made by embedding carbide particles in a metallic binder, providing high hardness and wear resistance.

- Q6: Define P-Type Cemented Carbide Tools.Ans: P-Type cemented carbide tools are designed for machining steel and other ferrous materials.

- Q7: Define K-Type Cemented Carbide Tools.Ans: K-Type cemented carbide tools are suitable for cutting cast iron and non-ferrous metals.

- Q8: Define M-Type Cemented Carbide Tools.Ans: M-Type cemented carbide tools are general-purpose tools for machining a variety of materials.

- Q9: Define Coating Materials.Ans: Coating materials are thin layers applied to cutting tools to improve hardness, wear resistance, and reduce friction.

- Q10: Name some Coating Materials.Ans: Common Coating Materials include:

- ➔ Titanium Nitride (TiN)

- ➔ Titanium Carbonitride (TiCN)

- ➔ Aluminum Oxide (Al₂O₃)

- ➔ Diamond coatings

- Q11: State some Coating Methods.Ans: Some of the Coating Methods are as follows:

- ➔ Physical Vapor Deposition (PVD)

- ➔ Chemical Vapor Deposition (CVD)

- Q12: Define Cermet.Ans: Cermet is a composite material made of ceramic and metallic materials, offering hardness and toughness.

- Q13: Name two basic types of cermets.Ans: The basic Types of Cermets are as follows:

- ➔ Titanium Carbide-based cermets

- ➔ Titanium Nitride-based cermets

- Q14: Define Ceramics.Ans: Ceramics are hard, brittle materials used for cutting tools that provide high wear resistance and heat resistance.

- Q15: Write some drawbacks of ceramics.Ans: Some of the drawbacks of Ceramics are as follows:

- ➔ Brittle, prone to chipping

- ➔ Limited toughness

- ➔ Cannot absorb shocks

- Q16: Define CBN Group.Ans: CBN (Cubic Boron Nitride) tools are extremely hard and used for machining hardened steels and superalloys.

- Q17: Define Diamond Group.Ans: Diamond tools are the hardest cutting tools, used for non-ferrous metals, plastics, and abrasive materials.

- Q18: Write Tungsten high speed steel grades.Ans: Tungsten High-Speed Steel Grades are as follows:

- ➔ T1, T2, T3, T4, T5

- Q19: Define Polycrystalline Compact.Ans: Polycrystalline Compact (PDC) is a synthetic diamond compacted with a metallic binder for high hardness cutting tools.

- Q20: Why are cemented carbide tools used?Ans: Cemented carbide tools are used because they provide high hardness, wear resistance, and can cut at higher speeds than HSS.

- Q21: Define PVD Coating.Ans: PVD (Physical Vapor Deposition) coating is a thin layer applied to cutting tools to improve hardness, wear resistance, and reduce friction.