Mechanical Workshop Tools & Their Uses | DAE Mechanical Guide

Master the tools every DAE Mechanical student must know. From lathe machines to drills, this guide explains practical workshop tools and their applications.

Introduction — A Complete Guide to Mechanical Workshop Tools

Mechanical workshop tools are the foundation of practical training for DAE Mechanical Engineering students in Pakistan. These tools are used in every aspect of mechanical work, from cutting and shaping metal to precise measuring and assembling components.

Understanding these tools not only prepares students for their coursework but also equips them with essential industry-ready skills. Whether you aim to become a mechanical technician, draftsman, or an engineer, mastering these tools is your first step toward a successful career.

In this guide, we will cover everything from basic hand tools to advanced machine tools, including safety equipment and practical tips for students. We will also include images, examples, and a comparison table to make learning easier.

Overview of Mechanical Workshop Tools

Mechanical workshop tools are instruments and machines designed to help perform various mechanical operations such as cutting, drilling, shaping, measuring, and assembling components. In a typical DAE Mechanical workshop, students encounter both **manual tools** and **machine tools**, which complement each other for practical training.

These tools are divided into categories:

- Hand Tools: Operated manually, used for fitting and assembly work.

- Measuring Tools: Essential for accurate measurements and quality control.

- Cutting Tools: Remove material from workpieces to shape parts.

- Machine Tools: Powered tools for heavy, precise, or repetitive tasks.

- Safety Tools: Protect students from injuries during workshop practice.

Proper knowledge and handling of these tools ensure efficiency, precision, and safety.

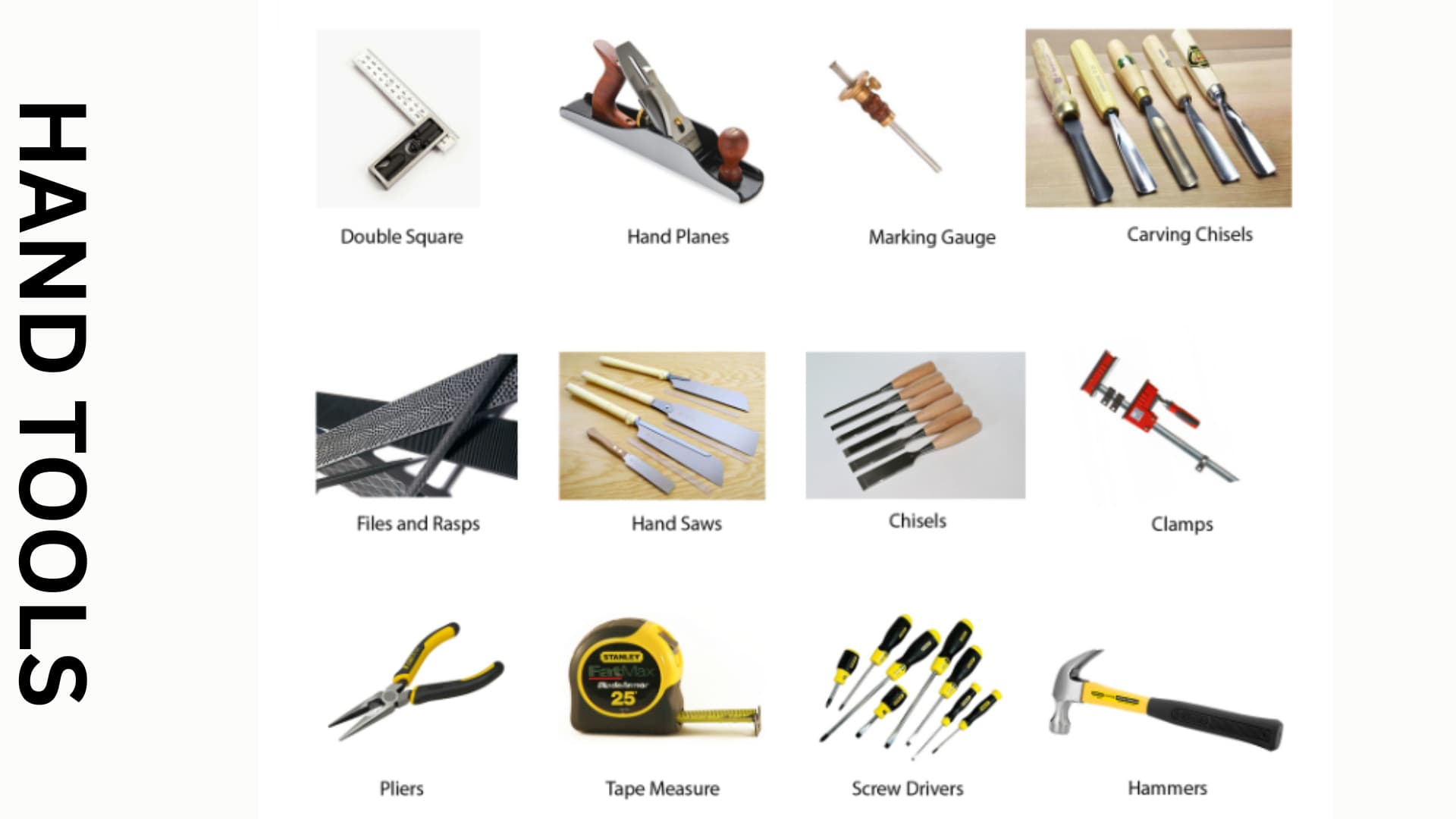

Hand Tools Used in Mechanical Workshop

Hand tools are manually operated instruments commonly used for assembling and fitting mechanical components. They are simple yet essential, and students must learn proper usage techniques.

- Hammer: Used for striking, fitting, or shaping work. Different types include claw hammer, ball-peen hammer, and sledgehammer.

- Screwdriver: Used to tighten or loosen screws. Comes in flathead, Phillips, and precision types.

- Spanner / Wrench: Used for tightening nuts and bolts. Adjustable spanners are very common in workshops.

- Pliers: Used for gripping, bending, and cutting wires or small objects. Includes needle-nose, slip-joint, and cutting pliers.

- File: Used to smooth, shape, or finish metal surfaces. Files vary in coarseness and shape depending on the task.

💡 Pro Tip: Always choose the correct size of tool to avoid damaging the workpiece or injuring yourself.

Measuring Tools and Their Uses

Measuring tools ensure accuracy, precision, and quality in mechanical work. Using these tools correctly is critical for producing components that meet required specifications.

- Steel Rule: Simple linear measurements for small components.

- Vernier Caliper: Precise measurement of internal and external diameters.

- Micrometer Screw Gauge: Measures thickness with high accuracy, often to 0.01 mm.

- Try Square: Checks right angles and ensures perpendicularity.

- Feeler Gauge: Measures gaps between two surfaces accurately.

Cutting Tools in Mechanical Workshop

Cutting tools remove excess material and shape components. They require careful handling to ensure safety and precision.

- Hacksaw: Cut metal rods, pipes, and profiles. Blade selection depends on material hardness.

- Chisel: Shape metal by cutting away unwanted sections.

- Drill Bit: Create precise holes in various materials.

- Reamer: Finish drilled holes for exact dimensions.

Machine Tools Used in Mechanical Workshop

Machine tools are powered instruments that allow precise, efficient, and repetitive mechanical operations. They are essential for producing high-quality components.

- Lathe Machine: Used for turning, facing, and threading cylindrical workpieces.

- Drilling Machine: Used to drill holes of different diameters accurately.

- Grinding Machine: Smooths surfaces and sharpens tools.

- Milling Machine: Cuts slots, gears, and complex shapes from solid materials.

Safety Tools and Equipment

Safety tools are critical to prevent injuries in workshops. Always wear the proper safety gear before starting any operation.

- Safety Gloves — Protect hands from cuts and burns.

- Safety Goggles — Protect eyes from sparks and debris.

- Helmet — Protects head from accidental impacts.

- Safety Shoes — Prevent foot injuries from heavy objects.

- Apron — Protects clothing and body from dirt and sharp objects.

Comparison Table of Mechanical Workshop Tools

The table below summarizes major tools, their categories, primary uses, and includes images for quick reference.

| Category | Tool Name | Primary Use | Image |

|---|---|---|---|

| Hand Tool | Hammer | Striking and fitting work |  |

| Hand Tool | Screwdriver | Tighten/loosen screws |  |

| Hand Tool | Spanner / Wrench | Tighten nuts and bolts |  |

| Hand Tool | Pliers | Gripping or cutting small objects |  |

| Hand Tool | File | Smooth and finish surfaces |  |

| Measuring Tool | Steel Rule | Linear measurements |  |

| Measuring Tool | Vernier Caliper | Precise internal/external measurements |  |

| Measuring Tool | Micrometer Screw Gauge | Accurate thickness measurement |  |

| Measuring Tool | Try Square | Check right angles |  |

| Measuring Tool | Feeler Gauge | Measure small gaps |  |

| Cutting Tool | Hacksaw | Cut metal rods and pipes |  |

| Cutting Tool | Chisel | Cutting and shaping metal |  |

| Cutting Tool | Drill Bit | Make holes |  |

| Cutting Tool | Reamer | Finish drilled holes |  |

| Machine Tool | Lathe Machine | Turning, facing, threading |  |

| Machine Tool | Drilling Machine | Drill holes accurately |  |

| Machine Tool | Grinding Machine | Surface finishing |  |

| Machine Tool | Milling Machine | Cut slots and gears |  |

| Safety Tool | Safety Gloves | Protect hands |  |

| Safety Tool | Safety Goggles | Protect eyes |  |

| Safety Tool | Helmet | Protect head |  |

| Safety Tool | Safety Shoes | Protect feet |  |

| Safety Tool | Apron | Protect body and clothes |  |

Importance of Workshop Tools for DAE Mechanical Students

Learning these tools is critical for DAE Mechanical students because practical knowledge is as important as theoretical understanding. Handling real equipment helps students:

- Gain hands-on experience and improve technical skills.

- Understand machine operations and safety precautions.

- Develop problem-solving skills while working on projects.

- Increase employability by preparing for industrial tasks.

💡 Pro Tip: Students should practice at least 1 hour daily in the workshop to reinforce learning.

Frequently Asked Questions (FAQs)

What are mechanical workshop tools?

Mechanical workshop tools are instruments used for cutting, measuring, shaping, and assembling mechanical components.

Why are workshop tools important for DAE Mechanical?

They provide practical skills and hands-on experience required for industrial and technical jobs.

Which tool is most commonly used in mechanical workshop?

Common tools include hammer, file, hacksaw, vernier caliper, and lathe machine.

Are mechanical workshop tools asked in exams?

Yes, questions related to workshop tools and their uses are common in DAE Mechanical theory and practical exams.

Conclusion — Mastering Mechanical Workshop Tools

Mechanical workshop tools are essential for DAE Mechanical students to build practical knowledge. From hand tools to advanced machine tools, understanding each tool's use ensures safety, efficiency, and precision in all mechanical operations.

By combining theoretical learning with hands-on practice, students prepare themselves for successful careers in mechanical industries. The comparison table, images, and examples provided here make this guide a comprehensive resource for students, instructors, and hobbyists alike.

Start exploring the workshop today, master each tool carefully, and remember: safety always comes first!