Safety Rules in Mechanical Workshop | DAE Mechanical Guide

Following strict safety rules in a mechanical workshop is essential for DAE Mechanical students to prevent accidents, ensure personal safety, and maintain equipment longevity.

Introduction — Workshop Safety Essentials

Proper safety rules in mechanical workshops are not just guidelines—they are life-saving practices. DAE Mechanical students must be aware of the hazards of working with machinery, tools, and chemicals. Following these rules ensures not only personal safety but also protects expensive equipment and promotes a disciplined learning environment.

Importance of Safety in Mechanical Workshop

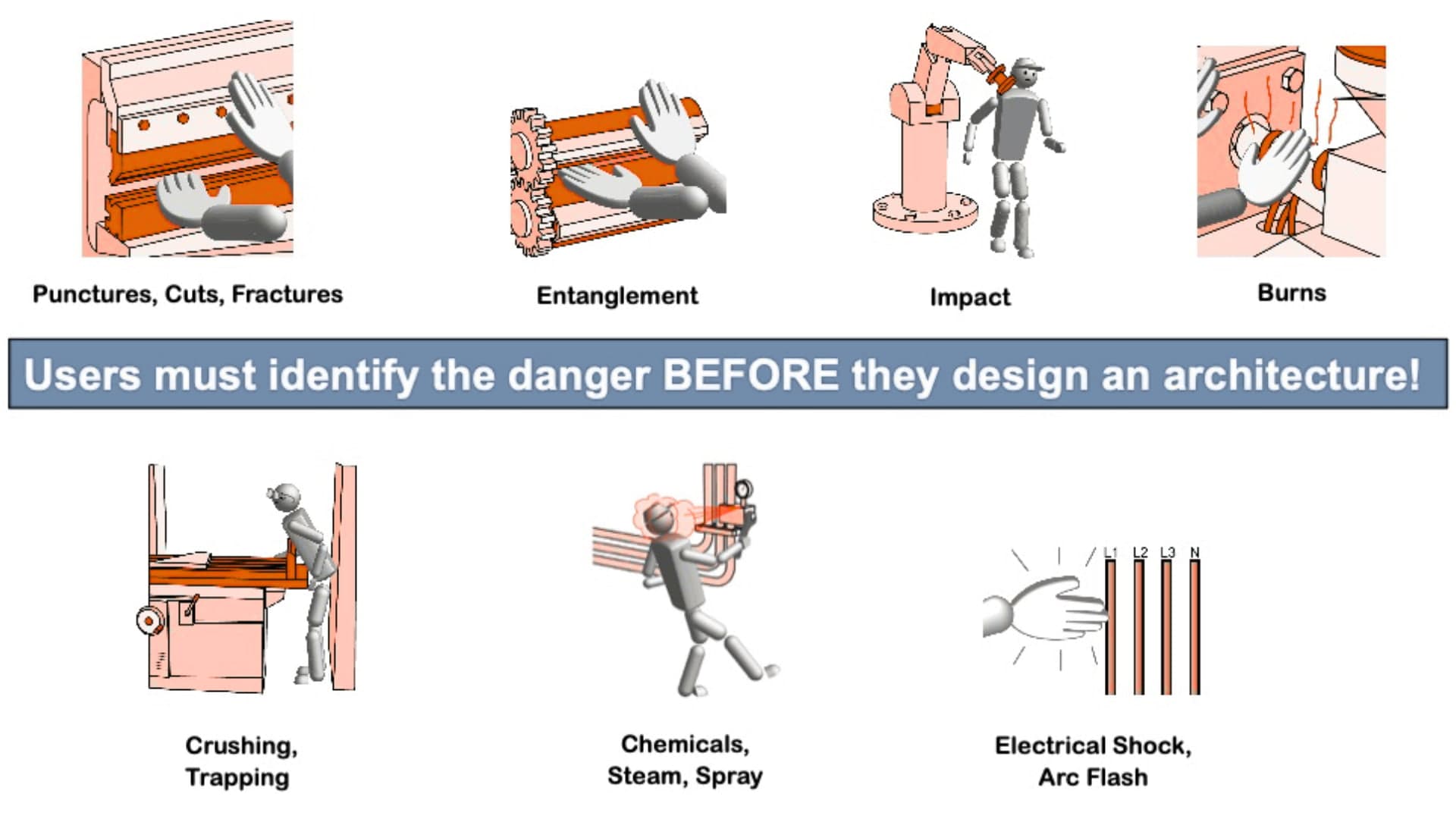

Mechanical workshops are inherently high-risk areas. Heavy machinery, sharp tools, hot surfaces, and moving parts pose a constant threat. Understanding workshop safety rules is crucial for:

- Preventing personal injuries

- Protecting expensive machines and tools

- Maintaining smooth workflow and productivity

- Instilling discipline and responsibility in students

Personal Protective Equipment (PPE)

PPE acts as the first line of defense in a workshop. Every student must wear:

- Safety goggles to prevent eye injuries from sparks or debris

- Protective gloves to avoid cuts, burns, or chemical exposure

- Aprons or lab coats to protect clothing and skin

- Safety shoes to guard against falling objects

- Helmets or headgear near heavy machinery

General Safety Rules

General safety practices that all students must follow include:

- Always work under supervision

- Keep your workspace clean and hazard-free

- Avoid running or playing in the workshop

- Do not touch or operate machines without permission

- Report accidents or spills immediately

- Follow posted safety signs and instructions

Machine Safety Rules

Machines are the heart of any workshop, but they can be dangerous without proper precautions:

- Inspect machines before use for defects

- Avoid loose clothing or jewelry

- Always use machine guards

- Turn off machines before maintenance

- Keep hands and tools away from moving parts

- Never leave running machines unattended

Tool Safety Rules

Proper tool handling prevents accidents and equipment damage:

- Use the correct tool for the task

- Inspect tools before use

- Do not use damaged or worn tools

- Store tools safely after use

- Keep sharp tools pointed away from yourself and others

Emergency Procedures

- Locate first aid kits, fire extinguishers, and emergency exits

- Follow fire safety instructions immediately

- Keep emergency exits clear

- Report accidents to instructors immediately

- Stay calm and follow safety protocols

Common Workshop Hazards vs Recommended PPE

| Hazard | Recommended PPE |

|---|---|

| Flying debris or sparks | Safety goggles, face shield |

| Sharp objects | Protective gloves |

| Falling heavy objects | Safety shoes, helmet |

| Hot surfaces or sparks | Gloves, apron, long sleeves |

Frequently Asked Questions (FAQs)

Why is safety important in mechanical workshops?

Safety prevents injuries, protects equipment, and ensures smooth workflow.

What PPE should students always wear?

Goggles, gloves, apron, safety shoes, and helmets as required.

What should I do in case of fire or accident?

Follow emergency procedures, use extinguishers if trained, and inform the instructor.

Can accidents be avoided?

Yes, by following safety rules, using PPE, and handling tools properly.

Are emergency exits important?

Yes, always keep exits clear and know their location for quick evacuation.

How often should machines be inspected?

Before each use to ensure proper functioning and safety.

Can I wear jewelry in the workshop?

No, loose jewelry or accessories can get caught in machines and cause injuries.

Is PPE mandatory for every workshop session?

Yes, PPE must always be worn for protection.

What is the first step in case of injury?

Apply first aid and report immediately to the instructor.

Are safety signs important?

Yes, they guide safe behavior and prevent accidents.

Conclusion: Adhering to mechanical workshop safety rules is essential for DAE Mechanical students. Proper PPE, awareness of hazards, and following emergency protocols create a safe and productive environment.